- A two-part addition curing silicone rubber;

- Lowest molecule weigth with ΣD3-12 <100ppm, outstanding thermal aging;

- Lower viscosity,Higher filler loading;

- Ideal for thermal interface materials.

CX-3151 LV Thermally Conductive Gel

Description

- CX-3151 is a two-part addition curing silicone rubber with mixing ratio of 1:1 by volume. It is easy to use, and cured at temperature and fast cured at high temperature.

- It features the lowest molecule weigth with ΣD3-12 <100ppm, offers lower viscosity and super flowability, improves blending of fluid and powder, decreases thermal resistance and increases thermal conductivity dramatically. It brings outstanding thermal aging and longer life span.

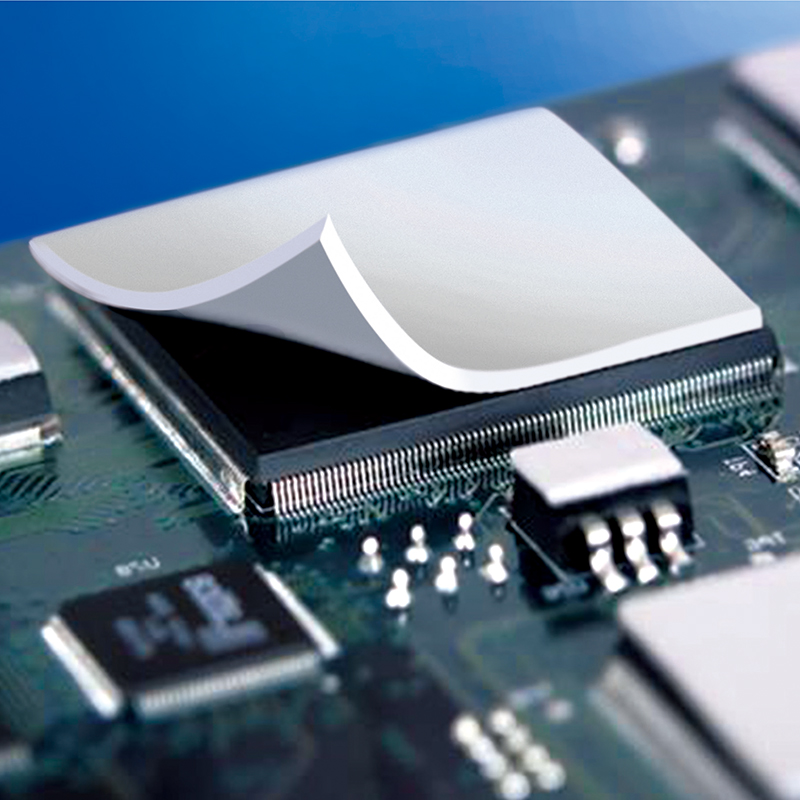

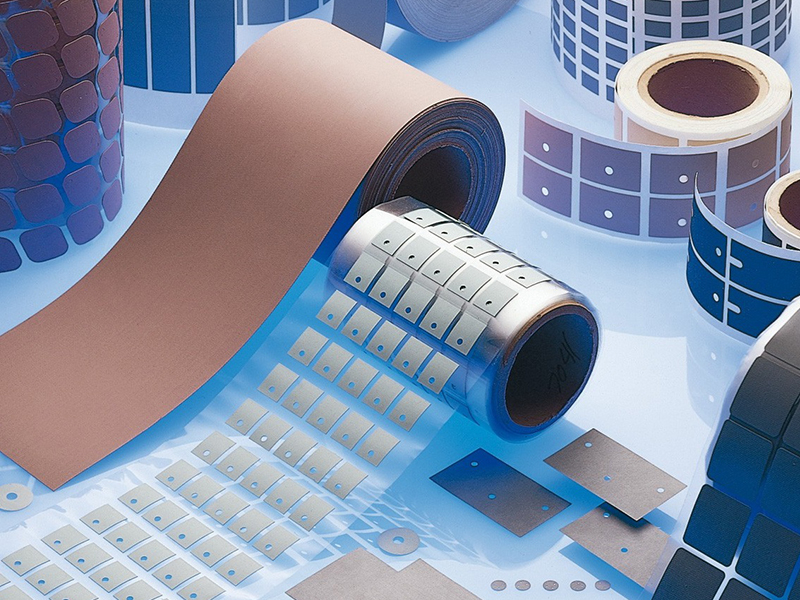

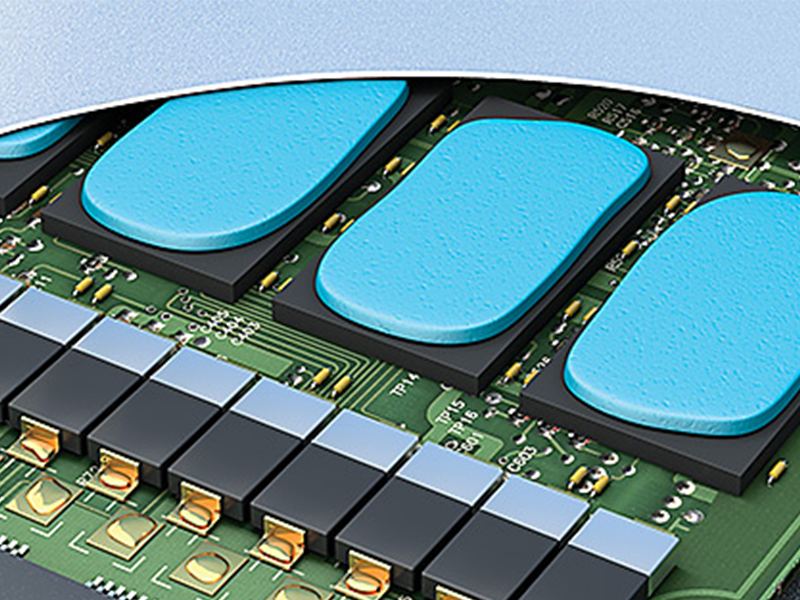

- It is widely used for thermal interface materials such as thermal pads, gels and greases, etc.

- It can be also used for encapsulating and potting sealant, electronic circuits, hybrid devices, small appliances, etc.

- Σ D3~D12<100

- Lowest oil-bleed

- Excellent wettability and thixotropy

- Higher filler loading

- Good tensile strength and softness

- Lower viscosity

- Two-part, 1:1 mixing ratio

- Higher thermal conductivity

- Outstanding thermal aging, excellent heat-resistance and cold-resistance

- Fast heat cure

- Excellent dielectric properties

| PARAMETER | UNIT | VALUE |

| Appearance | Transparent liquid | |

| Viscosity(25℃) | cSt | A=400±30 B=370±30 |

| Specific Gravity | 0.97 | |

| Pot Life (25℃) | hours | ≥7 |

| Cure Time(25℃) | mins | ≤20 |

| Platinum catalyst in which part | Part A | |

| Core penetration | 0.1mm | 120±10 |

| Dielectric constant | kHz | 2.8 |

| Dielectric strength | kV/mm | 23 |

| Volume resistivity | Ω・cm | 1×1015 |

| Dissipation Factor | 1kHz | 1×10-4 |

| Σ D3~D12 | ppm | <100 |

Reviews

There are no reviews yet.