- Good wettability and high filling rate

- Excellent resistance to high and low temperature and high humidity

- It is used in thermal conductive silicone sheet, automotive power supply, electronic component product insulation, etc.

CX-3110 SK Thermal Conductive Gel

Description

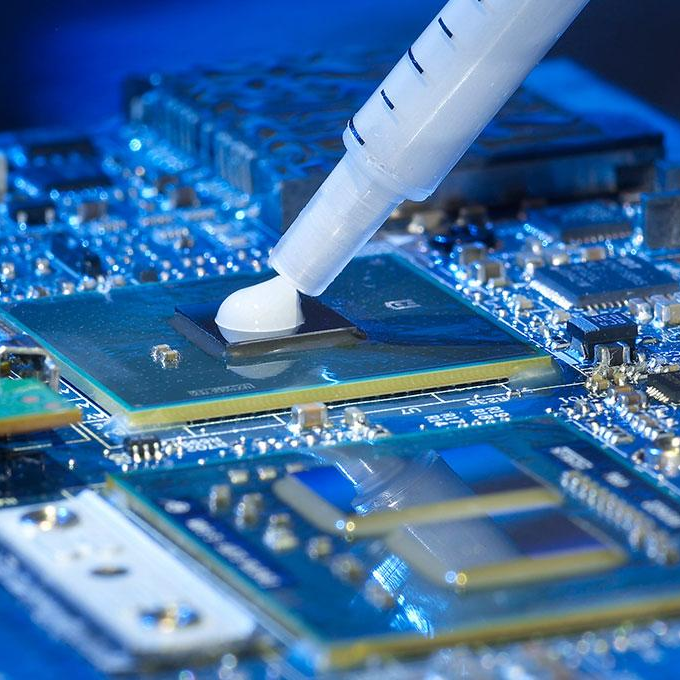

This product is an addition-molded silicone thermal conductive gel with very low viscosity, low molecular content and extremely low ion content, and can be heated to accelerate vulcanization. Low oil separation rate, no low molecules released during curing, the cured product has a small shrinkage rate, non-corrosive, stable chemical properties, and has the characteristics of moisture resistance, water resistance, ozone resistance, radiation resistance, and aging resistance.

FEATURES

- Good wettability and high filling rate

- Low viscosity, low oil separation rate

- Good thixotropy, high adhesion

- Crystal transparent gel, excellent fluidity

- Excellent electrical insulation

BENEFITS

- Large amount of powder, high thermal conductivity

- Excellent resistance to high and low temperature and high humidity

- Convenient production and use, simple operation

- Fast heat curing, low viscosity

| PARAMETER | UNIT | VALUE |

| Before Curing | ||

| Appearance | Colorless transparent oil | |

| Viscosity | mm²/s | A=100±20 B=100±20 |

| Operating time(25°C) | hr | ≥7 |

| Curing time(125°C) | min | ≤20 |

| The components of the platinum catalyst | A | |

| After Curing | ||

| Refractive Index | nD25 | 1.44 |

| Penetration 1/4 cone | 0.1mm | 120±10 |

| Dielectric Strength | kV/mm | 18 |

| Volume Resistivity | Ω·cm | 1*1015 |

| Low molecular content ∑D3~D20 | ppm | ≥500 |

Reviews

There are no reviews yet.