- Low viscosity suitable for coating process

- Excellent high and low temperature resistance and weather resistance (temperature -60℃~230℃)

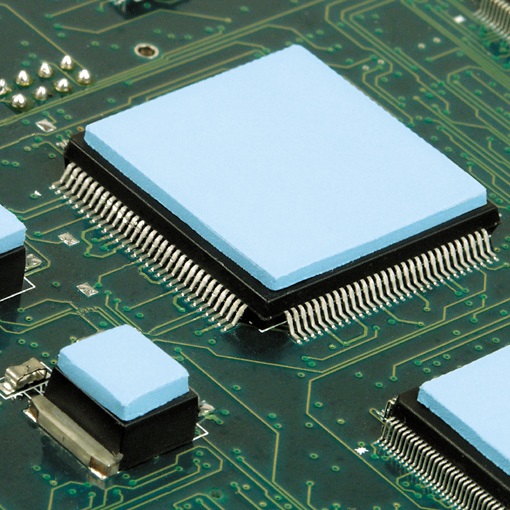

- It is applied to the coating of glass fiber and other fiber surface and the sealing and potting of various precision electronic components

CX-341AB Glass Fiber Coated Silicone Rubber

Description

This product is a two-component addition molding liquid silicone rubber. Both components have good fluidity. After mixing, it can be cured at room temperature or heated by heating. It has the characteristics of high temperature and fast curing. The shrinkage rate is low, no by-products are produced, and it is safe, non-toxic and tasteless. It can be used for the coating of glass fiber and other fiber surface, glass fiber casing, glass cylinder box, metal copper iron steel box, ceramic and PC, PP, ABS, PVC and other materials surface bonding and sealing.

FEATURES

- Low viscosity suitable for coating process

- Excellent anti-heating aging,good adhesion and resilience

- Excellent electrical insulation properties

- Addition type platinum vulcanization system

- Two-component, 1: 10 mixing ratio

BENEFITS

- Safe and environmentally friendly, no pollution

- Excellent high and low temperature resistance and weather resistance (temperature -60℃~230℃)

- Comply with USA FDA standard and European ROHS standard

| PARAMETER | UNIT | VALUE |

| Appearance | Translucent liquid | |

| Specific Gravity | g/cm³ | 1.14 |

| Viscosity(25°C) | mm²/s | A≤850 B≤60000±5000 |

| Operating Time(25°C) | hr | 24 |

| Curing Time(150°C) | min | ≥10 |

| Performance After Curing | ||

| Product Hardness | Shore A | 35±2 |

| Resilience | % | ≥70 |

| Dielectric Strength | KV/mm | 25 |

| Elongation | % | ≥300 |

| Tensile Strength | Mpa | ≥6.0 |

| Tear Strength | KN/m | ≥15 |

| Linear Expansion Coefficient | W(m⋅k) | ≥0.2 |

Reviews

There are no reviews yet.