- Low viscosity, low oil release rate

- Excellent high and low temperature resistance;fast heat curing

- Used in materials such as thermal silica gel, insulation, sealing potting, filling, etc.

CX-3212AB MQSilicone Resin Thermal Conductive

Description

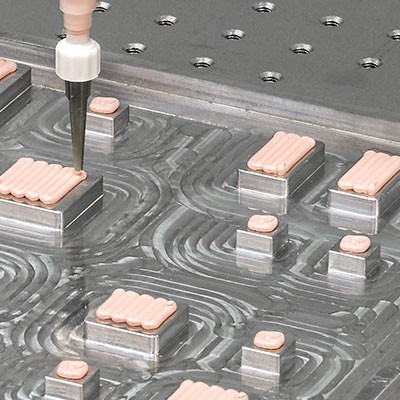

This product is a two-component addition molding room temperature curing MQ silicone resin thermal conductive gel, which can be heated to accelerate vulcanization (maximum temperature 150 ℃), low viscosity, low oil release rate and excellent adhesion. Products with different hardness can be obtained by adjusting the distribution ratio of group A and group B.

FEATURES

- Crystal transparent gel, excellent fluidity

- Low viscosity, low oil release rate

- Two-component, 1: 1 mixing ratio

- Excellent flame retardancy

- Excellent electrical insulation

- Addition type platinum vulcanization system

BENEFITS

- Convenient production and use, simple operation

- Safe and environmentally friendly, no pollution

- Excellent high and low temperature resistance

- Fast heat curing

| PARAMETER | UNIT | VALUE |

||

| CX-3212AB | CX-3213AB | |||

| Appearance | Colorless transparent liquid | Colorless transparent liquid | ||

| Viscosity | mm²/s | A=800±50 B=800±50 | A=800±50 B=800±50 |

|

| Specific gravity | g/cm³ | 0.95-0.98 | 0.95-0.98 | |

| Operating time(25°C) | hr | ≥7 | ≥7 | |

| Curing time(125°C) | min | 20 | 20 | |

| The components of the platinum catalyst | A | A | ||

| After Curing | ||||

| Refractive Index | nD25 | 1.41 | 1.41 | |

| Penetration | 0.1mm | 200±5 | 230±5 | |

| Dielectric content | 1kHz | 2.5 | 2.5 | |

| Dielectric Strength | kV/mm | 22 | 22 | |

| Volume Resistivity | Ω·cm | 1*1015 | 1*1015 | |

| Thermal conductivity | W/m·K | 0.2 | 0.2 | |

| Low molecular content ∑D3~D10 | ppm | <500 | <500 | |

| Flame retardant | UL 94HB | UL 94HB | ||

Reviews

There are no reviews yet.