- High tensile strength and tear strength

- Excellent heat resistance;low shrinkage

- It is widely used for casting wax, gypsum, resins, concrete and other materials

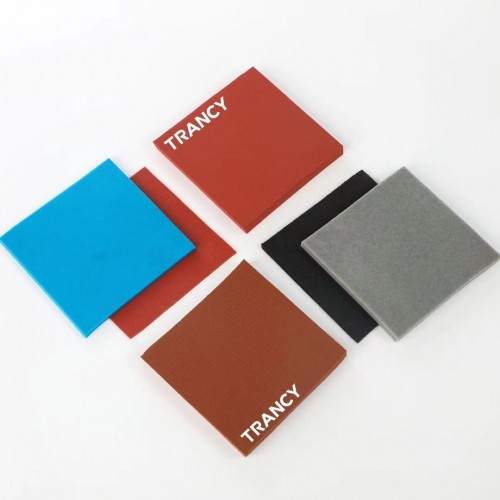

CX-31-40 Addition Cured Mold Making Silicone Rubber

Description

CX-31-40 is a two-part platinum-catalyzed silicone rubber with mixing ratio of 1:1 by volume. It offers good fluidity, low shrinkage and high tear-strength. It is easily mixed and poured, cured at room temperature and high temperature. It is suitable for casting polyester, epoxy, wax and a wide range of other casting materials.

FEATURES

- Excellentfluidity

- Lowshrinkage

- Superb heatresistance

- High tensile strength and tear strength

- Eco-friendly

BENEFITS

- Easy to use: is easily mixed and poured.

- Low shrinkage: shrinkage is less than 0.1%, and give accurate reproduction of mold making masters.

- Excellent heat resistance : work in a wide range of service temperature from -55℃ to250℃.

- Adjustable cure times andpot life: The pot life and cure times can be adjusted by plat-cat cure accelerator.

| PARAMETER | UNIT | VALUE | |||

| Appearance | Clear to slightly hazy liquid | ||||

| Viscosity | cP |

A:14,000±1,000 B:3,500±300 |

|||

| Specific gravity | g/cm³ | 1.15 | |||

| Mixing ratio | % | A:B=1:1 | |||

| Shrinkage | % | <0.1 | |||

| Hardness(Shore A) | 40 | ||||

| Port Life(25°C) | mins | 40 | |||

| Cure Time(25℃) | hours | 2-3 | |||

| Tensile Strength | Kgf/cm² | 80 | |||

| Tear Strength | Kgf/cm² | 18 | |||

| Elongation | % | 400 | |||

| Mixed Viscosity | cP | 8,000-9,000 | |||

Reviews

There are no reviews yet.