Applications

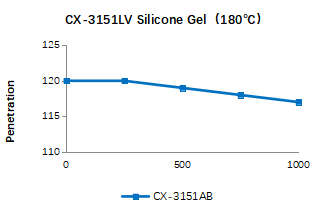

With more than 40 years of silicone R&D and manufacturing experience, Trancy focuses on developing high-performance thermally conductive silicone gels for thermal transfer materials, such as thermal pads, gels, adhesives and greases. Trancy has developed more than 100 types of silicone gels for thermal conductivity, and offers a wide range of selection for our customers. Whatever your requirements Trancy’s resources are readily available and our Technical Sales staff would welcome the opportunity to discuss them with you. Please do not hesitate to contact us.

Product Manager:Mr.Yu +86-177 2766 2733

![]() ILLUMINATE A BEAUTIFUL LIFE

ILLUMINATE A BEAUTIFUL LIFE

Trancy

Started in 1974, Trancy is a leader in silicone and solutions, committed to exploring and developing the applications of silicone materials. With more than 40 years of silicone R&D and manufacturing experience, Trancy provides more than 2000 silicone products and is able to produce tailor-made products based on your special demands.

Trancy Electronics Silicones

As a leading silicone manufacturer, Trancy focused on electrical and electronic applications, offering thermally conductive silicones, potting silicones and encapsulation products, adhesives, additives and optical bonding. Trancy provides protection for the next generation of smart electronics, increases their performance, efficiency and lifespan.

Product Manager :

Mr.Yu +86 177 2766 2733

winson.yu@trancytech.com

Whatsapp: +86 177 2766 2733

Inquiry Form