- High-performance specialty chemicals with low viscosity and good self-leveling in application

- Easy to apply, easy to operate, no primer is needed

- This silicone coating can be widely used in various types of reinforced concrete structures

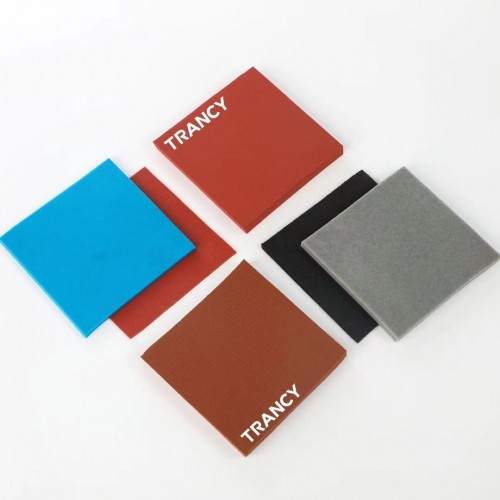

CX-9881 Silicone RTV Coating for Concrete Protection

Description

This product is a colorless and transparent liquid, a low molecular weight silicone oligomer, can penetrate into the concrete surface to chemically react with residual water by a moisture-curing mechanism to form an environmentally friendly waterproof polymer film. The thickness of the waterproof layer can be up to 3~12 mm, it can inhibit water absorption, produce waterproof, anti-Cl-, anti-ultraviolet properties and good gas permeability. It can effectively prevent the corrosion of the concrete and internal steel structure due to water seepage, sunshine, acid rain and seawater corrosion, flaking, mildew, and improve the service life of the building and still retain the original appearance.

FEATURES

- High-performance specialty chemicals with low viscosity and good self-leveling in application

- Good adhesion with deep penetration into the concrete surface

- Environmentally friendly, non-polluting, non-toxic, non-yellowing, and long service time period

- Authentic and inert film surface properties provide: good thermal stability, UV (sunlight)/ozone resistance (good weatherability), excellent chemical (oil/solvent) resistance, water resistance, flexibility, oxygen/air permeability, and high- & low-temperature properties, etc

BENEFITS

- Form 3~12 mm effective protective layer to improve the service life of buildings, e.g.

- Acid and alkali resistance, high- and low-temperature resistance, good weatherability, waterproof, antifouling, UV protection, scratch resistance, and flame retardance, etc.

- Easy to apply, easy to operate, no primer is needed

| PARAMETER | UNIT | VALUE |

| Appearance | Colorless transparent liquid | |

| Penetration depth | mm | ≥3.0 |

| 48hr Water absorption ratio | % | ≤10 |

| Chloride absorption reduction effect | % | ≥90 |

| After treatment concrete effect | Coulomb | ≤300 |

| Frost resistance (-20 to 20℃,20times) | No change in surface | |

| Heat resistance(180℃,4hr) | No change in surface | |

| Resistance to alkali resistance (soaked in saturated calcium hydroxide solution for 168 hr.) | No change in surface | |

| Acid resistance on the surface(1% hydroxide acid solution soaked for 168 hr) | No change | |

| Steel surface corrosion | No corrosion* |

Reviews

There are no reviews yet.