- Good internal viscosity and superior mechanical damping performance

- Addition type platinum vulcanization system

- Used in materials such as thermal silica gel, insulation, sealing potting, filling, etc.

CX-3612EH MQ Silicone Thermal Conductive Gel

Description

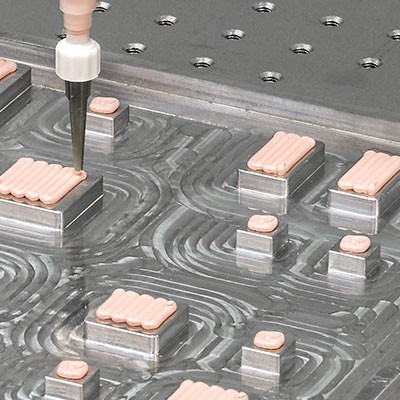

This product is a two-component addition molding room temperature curing MQ silicone resin thermal conductive gel, which can be heated to accelerate vulcanization (maximum temperature 150 ℃), low viscosity, low oil release rate and excellent adhesion. It is used to potting various automobiles, power electronic components, solar cells and other damping products. Products with different hardness can be obtained by adjusting the distribution ratio of group A and group B.

FEATURES

- Crystal transparent gel-like, low hardness, excellent elasticity

- Low viscosity, low oil release rate

- Two-component, 1: 1 mixing ratio

- Good internal viscosity and superior mechanical damping performance

- Excellent flame retardancy

- Excellent electrical insulation

BENEFITS

- Good liquidity and simple operation

- Fast heat curing

- Safe and environmentally friendly, no pollution

- Addition type platinum vulcanization system

| PARAMETER | UNIT | VALUE |

|

| CX-3612EH AB | CX-3613EH AB | ||

| Appearance | Colorless transparent liquid | Colorless transparent liquid | |

| Viscosity | mm²/s | A=800±50 B=800±50 |

A=800±50 B=800±50 |

| Specific gravity | g/cm³ | 0.95-0.98 | 0.95-0.98 |

| Operating time(25°C) | hr | ≥2 | ≥2 |

|

Curing time(125°C) |

min |

≤20 |

≤20 |

| The components of the platinum catalyst | A | A | |

| After Curing | |||

| Refractive Index | nD25 | 1.44 | 1.44 |

| Penetration | 0.1mm | 480±10 | 510±10 |

| Thermal expansion coefficient | m/mk | 1E-04 | 1E-04 |

| Dielectric content | 1kHz | 2.7 | 2.7 |

| Dielectric Strength | kV/mm | 23 | 23 |

| Volume Resistivity | Ω·cm | 1*1015 | 1*1015 |

| Thermal Conductivity | W/mk | 0.2 | 0.2 |

| Low molecular content | ppm | <500 | <500 |

| Flame retardant | UL 94HB | UL 94HB | |

Reviews

There are no reviews yet.